Advanced Welding Inspection Service for Design Applications

Unlocking the Trick Sorts Of Welding Solutions for Your Tasks

In today's landscape of diverse welding solutions, recognizing the nuances and applications of various welding techniques is extremely important for successful task implementation - Welding Inspection Service. By unwinding the essential kinds of welding solutions offered, one can browse the complexities of selecting the most ideal approach to make sure accuracy, efficiency, and quality in welding jobs.

Common Welding Strategies

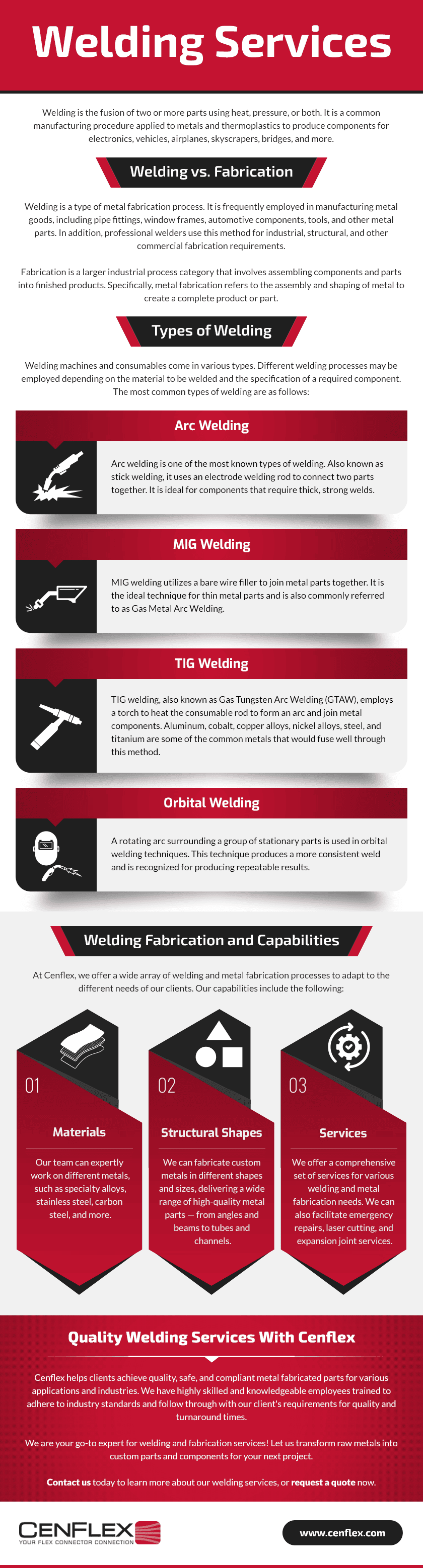

A number of typically made use of welding methods play important functions in various commercial fields. One of the most extensively made use of approaches is Gas Metal Arc Welding (GMAW), also known as MIG welding.

An additional popular welding strategy is Gas Tungsten Arc Welding (GTAW), commonly described as TIG welding. TIG welding makes use of a non-consumable tungsten electrode to create the weld and calls for a separate filler material. This method is favored for its control, accuracy, and capacity to create high-grade welds on slim products.

Shielded Metal Arc Welding (SMAW), or stick welding, is an additional vital technique where a flux-coated electrode is utilized to create the weld. SMAW is known for its simpleness, flexibility, and suitability for on-site and outside welding applications. These common welding strategies are crucial for fabricating frameworks, machinery, and different devices across markets.

Advanced Welding Procedures

Advanced welding processes include cutting-edge strategies that press the boundaries of conventional welding techniques in terms of performance, adaptability, and precision. One such process is laser light beam welding, which makes use of a focused beam to sign up with steels with very little heat-affected zones, making it suitable for high-precision or fragile tasks. In addition, electron beam of light welding utilizes a high-velocity electron beam to create deep welds in thick products, providing remarkable toughness and quality.

Furthermore, friction stir welding is a solid-state signing up with procedure that uses a rotating device to create frictional heat, bonding products without thawing them. This method is specifically valuable for joining lightweight alloys with remarkable mechanical residential or commercial properties. An additional innovative method is ultrasonic welding, where high-frequency ultrasonic vibrations are utilized to produce solid-state welds in plastics, steels, and other materials, offering tidy and fast joining solutions.

These progressed welding processes deal with a diverse variety of commercial requirements, providing effective, top notch, and precise services for various jobs, from aerospace elements to automotive parts and past.

Specialized Welding Applications

Automated Welding Solutions

In contemporary commercial settings, the application of automated welding services has reinvented manufacturing procedures by improving efficiency and accuracy. Automated welding systems use advanced technologies such as robotics, computer system numerical control (CNC), and man-made intelligence to carry out welding jobs with minimal human treatment (Welding Inspection Service). These systems use various advantages, consisting of increased performance, enhanced weld high quality, and lowered manufacturing costs

One trick benefit of automated welding solutions is their ability to constantly generate premium welds, leading to improved general item high quality. In addition, these systems can run constantly, 24/7, without the requirement for breaks, causing greater outcome degrees and faster job conclusion times. By using automated welding options, firms can additionally minimize the threats linked with human mistake, ensuring greater accuracy and repeatability in the welding procedure.

Moreover, automated welding solutions are very functional and versatile to numerous welding applications, from detailed elements to large structures. Whether in automobile production, aerospace industries, or building and construction projects, the integration of automated welding systems provides a competitive side by simplifying procedures and delivering superior welding results.

Ingenious Welding Technologies

The evolution of automated welding remedies has actually led the way for the integration and advancement of cutting-edge welding innovations in modern commercial applications. One such sophisticated modern technology is laser beam of light welding, which utilizes an extremely focused beam of light to sign up with metal parts with accuracy and effectiveness. This method is specifically beneficial for projects needing elaborate welds on products with high melting points or for applications where minimal heat-affected areas are important.

Another ingenious welding innovation obtaining appeal is friction stir welding (FSW), a solid-state joining procedure that produces high-strength bonds by producing frictional warm between two items of metal. FSW is extensively made use of in markets such as aerospace and auto for its capacity to create welds with premium mechanical homes and improved structural stability.

In addition, electron beam of light welding (EBW) is an my latest blog post innovative strategy that utilizes a light beam of high-velocity electrons to produce precise, deep welds in steel components. This technology is preferred for its ability to weld different metals and products with varying densities efficiently. As sectors proceed to demand better and efficiency in welding procedures, these cutting-edge innovations are poised to play a significant role in forming the future of commercial welding applications.

Verdict

To conclude, comprehending the key kinds of welding services is crucial look at this now for effectively finishing a variety of jobs. From typical welding strategies to sophisticated processes, specialized applications, automated options, and cutting-edge modern technologies, each approach uses distinct advantages and applications. By familiarizing on your own with these numerous welding choices, you can select one of the most appropriate strategy for your certain task demands and achieve top quality results.

In today's Continued landscape of varied welding solutions, comprehending the subtleties and applications of different welding methods is critical for effective job implementation. By unwinding the key types of welding solutions available, one can navigate the details of choosing the most suitable approach to make certain accuracy, performance, and top quality in welding tasks. As we get started on this expedition of welding services, a much deeper understanding into the globe of welding awaits, promising insights that can elevate the results of your jobs.